Preserving the Harvest, Protecting the Future.

At Kuwala, food preservation is not simply a farming practice—it is an investment in resilience, dignity, and self-sustainability. This season marks a significant milestone with the construction of Kuwala’s first-ever food preservation building, a purpose-built space designed to extend the life of each harvest and bridge the gap between growing seasons.

Across Malawi, the need for solutions like this has never been more urgent. Climate-driven floods and prolonged droughts have devastated crops, pushing national maize production far below demand. As food prices rise and reserves shrink, millions of Malawians face increasing food insecurity. These challenges demand a fundamental shift in how food is grown, stored, and preserved.

In response, Kuwala is expanding beyond traditional farming methods to rethink what happens after the harvest. The new food preservation building—modest in form but powerful in impact—provides a protected environment for cleaning, sorting, canning, and storing produce. In a context where preservation is uncommon and crops are often consumed immediately or spoiled, this structure represents a critical step toward long-term food security.

Inside, every design decision works with purpose. Thoughtful layouts streamline workflows and elevate food safety, with dedicated spaces to gather, sort, and prepare produce before it moves to washing stations equipped with sinks and running water. These intentional yet straightforward choices protect the harvest—keeping food fresher, safer, and usable long after it leaves the field.

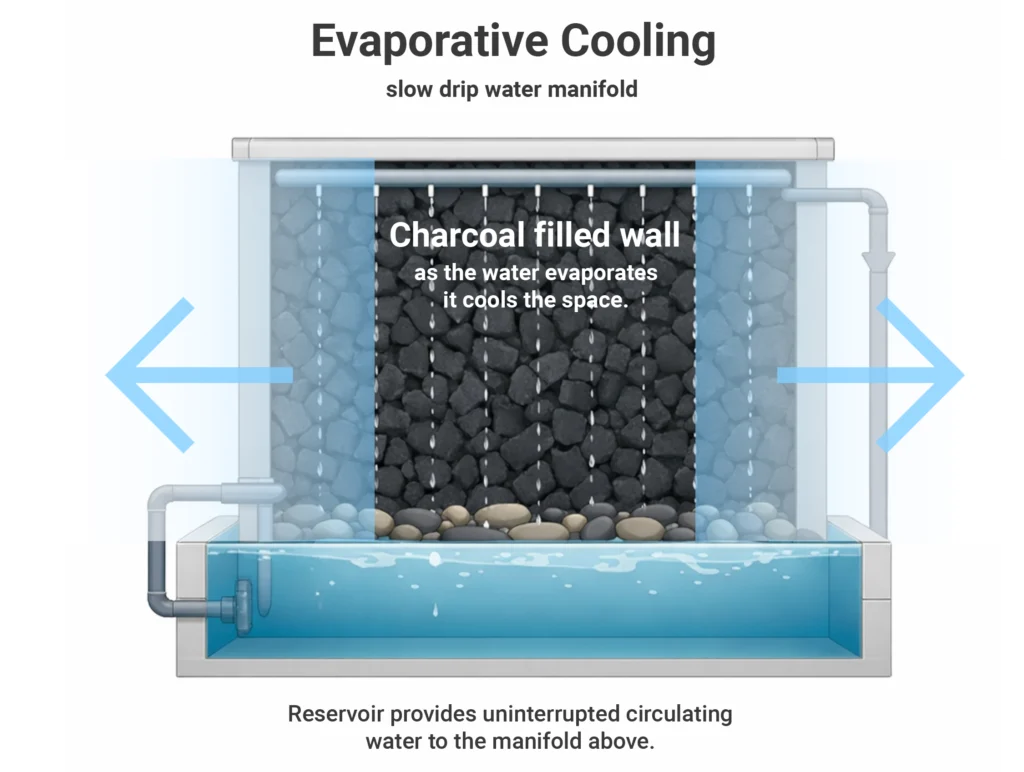

At the heart of the farm, innovation takes root. A revolutionary cold-storage system hums without a single watt of electricity. Charcoal-lined walls and a slow-drip water system work in quiet harmony, pulling heat away as water evaporates and keeping produce fresh longer. This zero-energy marvel isn’t just an experiment—it’s a bold proof-of-concept, with every temperature shift and seasonal change meticulously tracked to unlock its full potential.

Charcoal is doing a few useful jobs in that wall.

Huge wet surface area = better evaporative cooling.

Evaporative cooling depends on water spreading into a thin film and having lots of air contact. Charcoal (especially chunk / biochar-like material) is porous and rough, so it:

- Wicks water across the surface

- Breaks water into thin layers

- Keeps more of the wall evenly damp

That increases evaporation per square metre, so you get more cooling for the same drip rate.

Low energy requirements.

Because charcoal is absorbent and capillary-active, to self-distribute water downward and sideways, which helps a simple drip line work better and reduces “dry stripes.” Water can be supplied by a small solar-powered pump or gravity-fed from a water tower.

Adsorption: can reduce some odours/pollutants.

Charcoal is famous for adsorbing certain volatile compounds and odours. In an air path, it can slightly “clean up” incoming air (how much depends on airflow rate, charcoal type, and maintenance).

Here, the farm becomes a living laboratory. Curiosity meets action. Ideas are tested, refined, and reimagined. Success here won’t stay confined to one building—it can scale across campus and extend into surrounding communities, offering a climate-smart, affordable blueprint for preserving food. From seed to storage, Kuwala turns inspiration into impact, honouring every harvest, cutting waste, and strengthening food security—one brilliant innovation at a time.